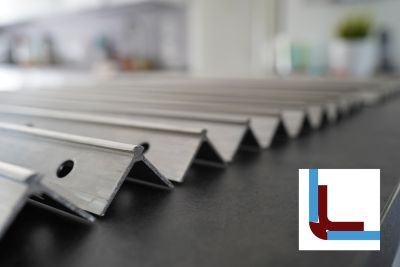

High-volume production of complex open and closed profiles from steel, stainless steel, and aluminum.

Inline punching and stamping processes integrated directly into the profiling lines for maximum efficiency.

In-house development and manufacturing of roll forming tools and punching dies to ensure rapid prototyping.

Precision laser welding for closed profiles with minimal heat distortion and superior seam quality.

Complete component assembly including joining, fastening, and packaging for direct-to-line delivery.

Certified according to ISO 9001:2015. Optical measuring systems guarantee consistent profile geometry.

PL Profil specializes in the processing of ultra-high-strength steels and complex material combinations. Our state-of-the-art roll forming lines handle material thicknesses from 0.3mm to 4.0mm with extreme precision.